IoT Building Automation: 10 Proven EasyIO Benefits for Smarter Facilities

In today’s rapidly evolving world, IoT Building Automation in the UAE is redefining how modern buildings are designed, operated, and maintained. Across the emirates of Dubai, Abu Dhabi, and Sharjah, developers and facility managers are turning to Internet of Things (IoT) technologies to achieve smarter control, better energy efficiency, and enhanced occupant comfort.

The Internet of Things has become a powerful driver of innovation in building automation, transforming how systems are monitored, controlled, and optimized in real time. For UAE building owners and facility managers, IoT is no longer just a global trend, it is the foundation for creating intelligent, sustainable, and compliant smart buildings built for the region’s climate and energy goals.

IoT Building Automation is the convergence of traditional building management systems with internet-native sensors, controllers, and analytics. For technical teams this means redesigning control strategies so they run on data, not on fixed schedules. The result is better operational visibility, measurable energy savings, and predictable operations.

Key shift for engineers and facility managers: move from reactive maintenance to predictive operations, and from isolated control loops to federated analytics. This shift changes how control strategies are designed, tested, and validated.

EasyIO delivers controllers that support modern protocols and cloud connectivity. For engineers, this reduces the need for custom gateways and accelerates integration with analytics platforms. For facility managers, EasyIO provides dashboards and historical data that are actionable.Important technical advantages:

These attributes make EasyIO a practical choice for phased IoT upgrades that must coexist with legacy equipment.

Below I expand the original benefit list to an engineer-focused 10 point set with practical implications and KPIs.

A reliable IoT Building Automation solution is a stack. Each layer must be specified and validated.

Core layers and components:

Protocol notes for engineers:

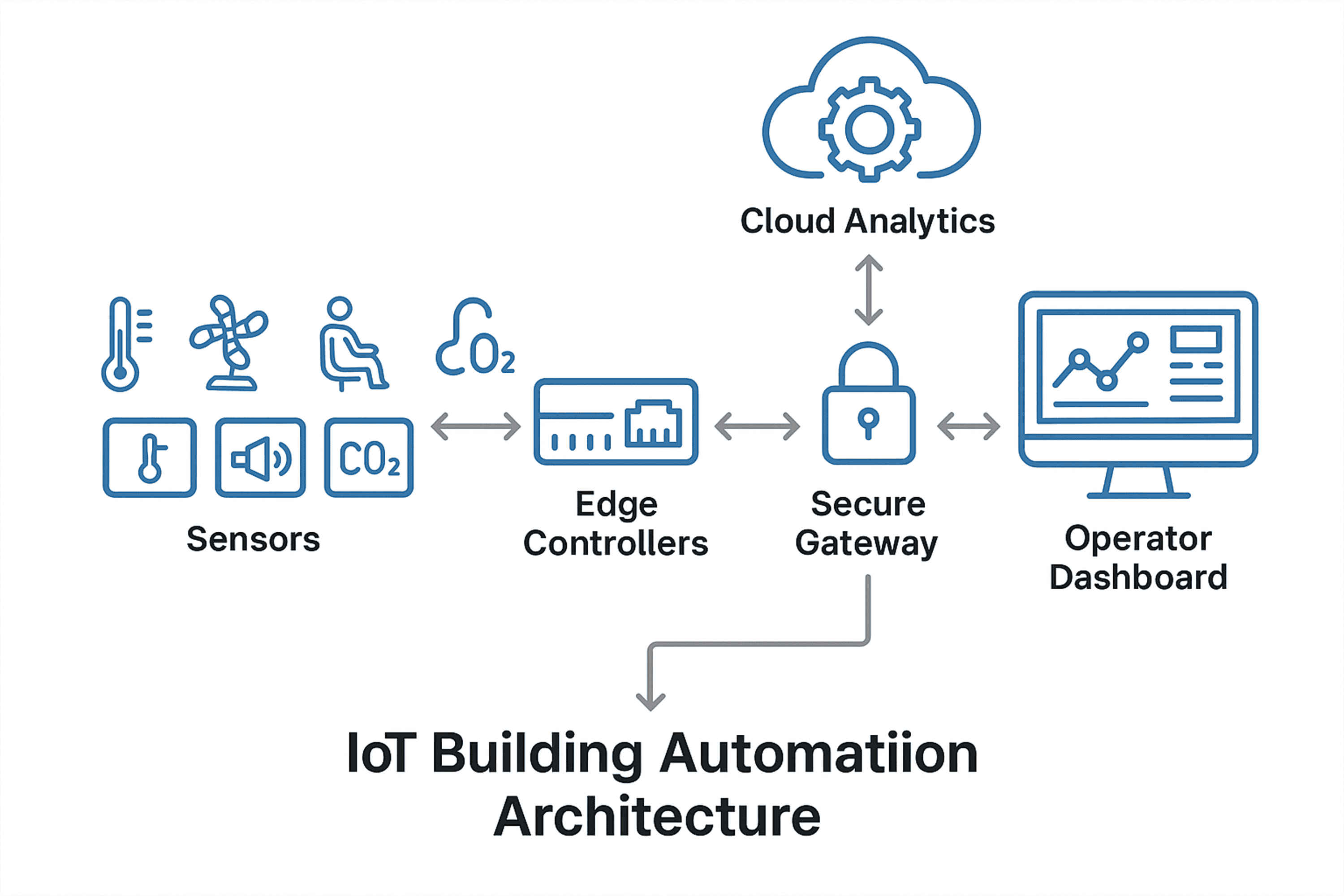

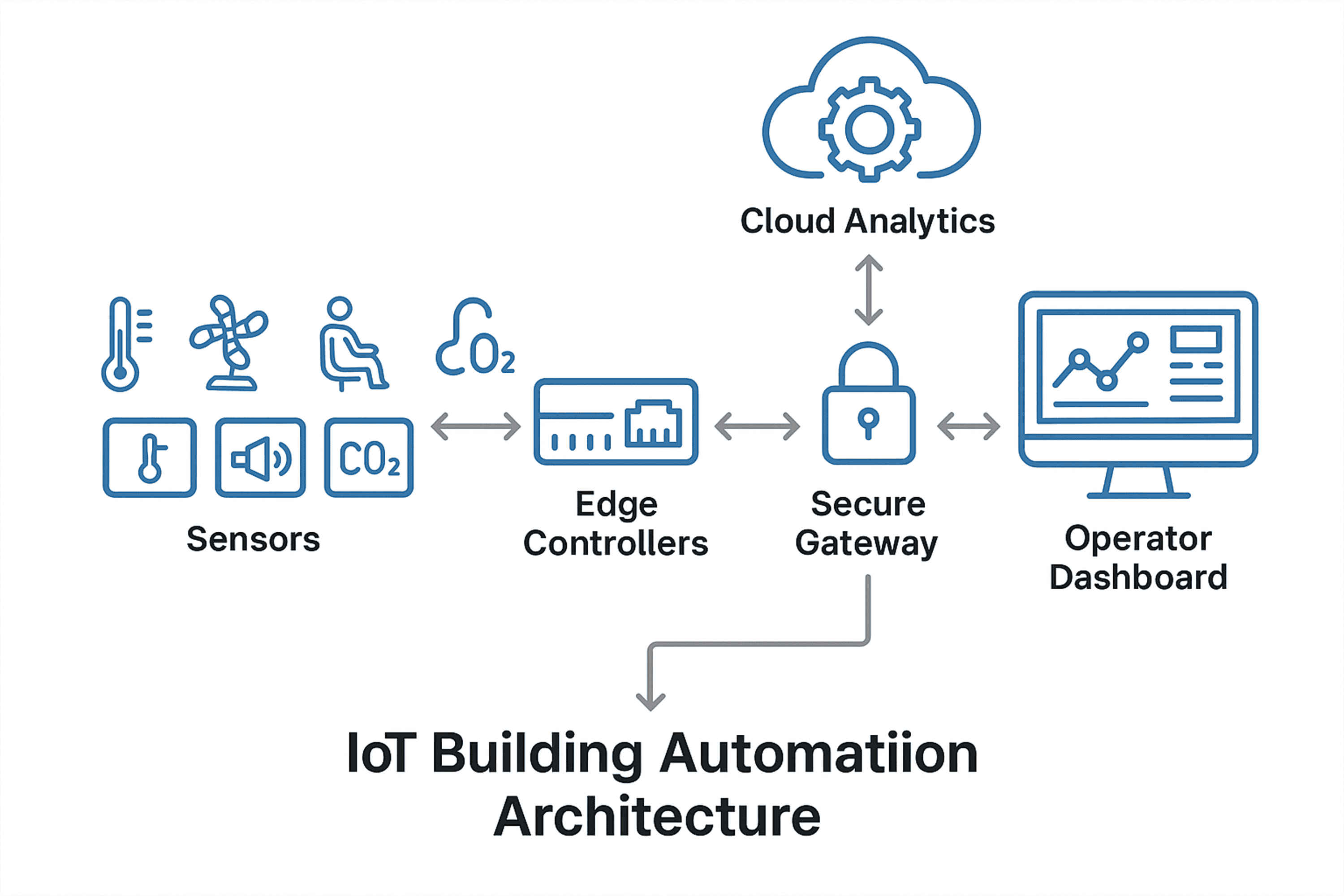

A typical IoT Building Automation architecture is built as a layered system that ensures reliability, scalability, and security. Each layer has a distinct role, and together they form a resilient control and monitoring stack.

Core layers in IoT Building Automation systems:

Key takeaway for engineers: An IoT Building Automation system must preserve local autonomy at the controller level, even when network or cloud services are interrupted. This ensures business continuity while still benefiting from cloud-scale analytics.

When moving from design to operations, engineers must consider deployment sequencing.

Recommended deployment patterns:

This separation of architecture (system layers) and deployment (rollout strategy) gives both engineers and facility managers clarity on design versus implementation responsibilities.

Tip for procurement: require a factory acceptance type checklist that includes telemetry accuracy, protocol conformance, and security controls.

Security must be designed not bolted on. Key practices for BMS engineers:

Operational resilience points:

Interoperability reduces vendor lock in and accelerates future upgrades. Best practices:

Data modeling tip: adopt a simple naming taxonomy such as

A strong IoT Building Automation business case must connect technical performance to financial and strategic outcomes. Engineers focus on KPIs such as uptime and energy intensity, while executives evaluate cost reduction, compliance, and return on investment.

Core KPI categories for IoT Building Automation:

ROI approach for IoT Building Automation projects:

Why this matters for decision makers: Linking technical KPIs directly to operational savings and ESG outcomes ensures IoT Building Automation is not only an engineering upgrade but also a strategic investment that improves competitiveness and compliance.

Applied examples for engineers and project managers:

For more details on chiller plant optimization and building management, explore our service page.You may also find useful insights in reports from MarketsandMarkets, McKinsey, and other IoT industry publications.

IoT building projects often face recurring challenges. Below are common issues with practical mitigation strategies:

Plan for the next wave of capabilities:

Suggested internal link for sales and discovery: /service/

IoT Building Automation is not a product, it is a capability set that requires strategy, engineering discipline, and operational ownership. EasyIO controllers provide the building blocks, and Dew Tech provides the local delivery capability for the Middle East.

Next steps for technical teams:

Contact Dew Tech for a site assessment and pilot program planning.

The Internet of Things has become a powerful driver of innovation in building automation, transforming how systems are monitored, controlled, and optimized in real time. For UAE building owners and facility managers, IoT is no longer just a global trend, it is the foundation for creating intelligent, sustainable, and compliant smart buildings built for the region’s climate and energy goals.

1. The IoT revolution for buildings

IoT Building Automation is the convergence of traditional building management systems with internet-native sensors, controllers, and analytics. For technical teams this means redesigning control strategies so they run on data, not on fixed schedules. The result is better operational visibility, measurable energy savings, and predictable operations.

Key shift for engineers and facility managers: move from reactive maintenance to predictive operations, and from isolated control loops to federated analytics. This shift changes how control strategies are designed, tested, and validated.

2. Why EasyIO From Johnson Controls Is Relevant To BMS Engineers And Facility Managers

EasyIO delivers controllers that support modern protocols and cloud connectivity. For engineers, this reduces the need for custom gateways and accelerates integration with analytics platforms. For facility managers, EasyIO provides dashboards and historical data that are actionable.Important technical advantages:

- Native support for BACnet and Modbus where required

- MQTT and lightweight telemetry for cloud integration

- Local control capability so critical loops remain operational even if network services are interrupted

These attributes make EasyIO a practical choice for phased IoT upgrades that must coexist with legacy equipment.

3. These 10 benefits show why IoT Building Automation is now essential for engineers and facility managers

Below I expand the original benefit list to an engineer-focused 10 point set with practical implications and KPIs.

- Real time monitoring and control: Live telemetry from sensors and controllers, visualized in dashboards. Why it matters: Faster detection of anomalies leads to faster corrective action. Key KPI: Mean time to resolution for critical alarms.

- Energy efficiency and demand optimization: Continuous energy profiling of systems and loads, enabling demand response and peak shaving. Why it matters: Reduces utility costs and exposure to demand charges. Key KPI: kWh reduction and peak demand reduction percentage.

- Predictive maintenance and fault detection: Machine learning or rule-based analytics identify deviations that precede failures. Why it matters: Reduces unplanned downtime and extends asset life. Key KPI: Reduction in unplanned downtime hours.

- Improved occupant comfort and environment control: Dynamic setpoint adjustments based on occupancy, CO₂ levels, and thermal mapping. Why it matters: Better occupant satisfaction and productivity. Key KPI: Occupant comfort score or complaint rate.

- Cost optimization through operational analytics: Identify inefficiencies such as simultaneous heating and cooling or poor sequencing. Why it matters: Lowers OPEX without replacing equipment. Key KPI: Operational cost per square meter.

- Integration with legacy systems for staged modernization: Gateways and protocol bridges allow old systems to join the IoT fabric. Why it matters: Preserves capital investment while enabling digital services. Key KPI: Percent of systems integrated without hardware replacement.

- Scalability for large campuses and multi-site portfolios: Modular controllers and cloud tenancy models allow central management across sites. Why it matters: Easier standardization and centralized policy enforcement. Key KPI: Time to onboard a new site.

- Data driven decision making and analytics: Historic and trend data enables root cause analysis and long term optimization. Why it matters: Supports investment decisions and continuous commissioning. Key KPI: Number of evidence-driven improvement projects per quarter.

- Support for sustainability and ESG objectives Description: Continuous monitoring of consumption supports emissions reporting and certification. Why it matters: Regulatory compliance and investor expectations. Key KPI: Reduction in carbon intensity per square meter.

- Improved security and controlled access to operational data Description: Properly designed IoT architecture includes authentication, role-based access, and encrypted telemetry. Why it matters: Protects critical systems and data privacy. Key KPI: Number of security incidents and time to containment.

4. Key technical components and protocols

A reliable IoT Building Automation solution is a stack. Each layer must be specified and validated.

Core layers and components:

- Sensors and field instruments, for example temperature, humidity, occupancy, CO₂, and power meters

- Edge controllers capable of local control logic and secure telemetry, such as EasyIO controllers

- Protocol translation and gateway services supporting BACnet, Modbus, MQTT, and REST APIs

- Secure network infrastructure with VLAN separation and firewall policies

- Cloud or on-prem data platforms for analytics and long term storage

- Visualization and reporting layers for operators and management

Protocol notes for engineers:

- BACnet remains the de facto for HVAC control and is supported in many EasyIO controllers

- Modbus is widely used for meters and drives

- MQTT is preferred for efficient telemetry to cloud systems

- APIs should be RESTful with token-based authentication for integration with analytics

5. IoT Building Automation architecture and system layers

A typical IoT Building Automation architecture is built as a layered system that ensures reliability, scalability, and security. Each layer has a distinct role, and together they form a resilient control and monitoring stack.

Core layers in IoT Building Automation systems:

- Sensors and field devices: Capture temperature, humidity, CO₂, occupancy, vibration, and energy usage data.

- Edge controllers: Execute local control logic while ensuring secure communication with higher layers. EasyIO controllers are a strong fit here.

- Protocol and gateway services: Provide translation across BACnet, Modbus, MQTT, and REST APIs for seamless integration.

- Secure networking: Uses VLAN segmentation, firewalls, and QoS rules to protect operational traffic.

- Data platforms: Cloud or on-prem solutions for advanced analytics, trend storage, and reporting.

- Visualization and operator consoles: Dashboards and HMIs that deliver actionable insights to facility managers.

Key takeaway for engineers: An IoT Building Automation system must preserve local autonomy at the controller level, even when network or cloud services are interrupted. This ensures business continuity while still benefiting from cloud-scale analytics.

6. Deployment patterns for reliable rollouts

When moving from design to operations, engineers must consider deployment sequencing.

Recommended deployment patterns:

- Start with single system pilots (e.g., AHU, chiller plant) to validate telemetry accuracy and control logic.

- Progress to phased rollouts by equipment type or building zone.

- Apply configuration templates across multiple sites to standardize and reduce commissioning errors.

- Maintain centralized monitoring consoles for multi-site operations.

This separation of architecture (system layers) and deployment (rollout strategy) gives both engineers and facility managers clarity on design versus implementation responsibilities.

Tip for procurement: require a factory acceptance type checklist that includes telemetry accuracy, protocol conformance, and security controls.

7. Cybersecurity and operational resilience best practices

Security must be designed not bolted on. Key practices for BMS engineers:

- Network segmentation and VLAN for operational technology networks

- Use TLS or secure WebSocket for telemetry transport rather than plaintext protocols

- Implement certificate management and rotate credentials on a schedule

- Role based access control for consoles and APIs

- Monitoring and logging of controller health and telemetry integrity

- Plan for secure firmware updates and vendor attestations

Operational resilience points:

- Ensure controllers can operate autonomously if cloud connectivity is lost

- Backup configuration and baseline control logic for quick restore

- Define change control for control strategies with versioning

8. Integration and interoperability considerations

Interoperability reduces vendor lock in and accelerates future upgrades. Best practices:

- Prefer open protocols and documented APIs for new deployments

- Validate BACnet object models and units early in the project

- Use middleware or normalization layers if multiple vendors and protocols must coexist

- Map data points and units to consistent naming conventions for analytics ingestion

Data modeling tip: adopt a simple naming taxonomy such as

site_building_system_point so analytics can be automated.9. ROI from IoT Building Automation: Business Case for Engineers and Executives

A strong IoT Building Automation business case must connect technical performance to financial and strategic outcomes. Engineers focus on KPIs such as uptime and energy intensity, while executives evaluate cost reduction, compliance, and return on investment.

Core KPI categories for IoT Building Automation:

- Energy efficiency: Reduction in kWh per square meter and avoided peak demand charges.

- Maintenance costs: Fewer unplanned failures and increased mean time between failures (MTBF).

- Occupant satisfaction: Comfort scores, complaint rates, and productivity correlations.

- Sustainability metrics: Carbon intensity per square meter and progress toward ESG targets.

- Commissioning and service efficiency: Percentage of issues resolved within SLA.

ROI approach for IoT Building Automation projects:

- Establish a baseline for energy and maintenance costs.

- Model conservative savings from predictive controls, optimized scheduling, and continuous commissioning.

- Capture soft benefits such as asset life extension and reduced occupant disruption.

- Report progress with dashboards and quarterly reviews to maintain stakeholder alignment.

Why this matters for decision makers: Linking technical KPIs directly to operational savings and ESG outcomes ensures IoT Building Automation is not only an engineering upgrade but also a strategic investment that improves competitiveness and compliance.

10. Real World Examples and Applied Use Cases

Applied examples for engineers and project managers:

- Chiller plant sequencing: use IoT telemetry to change pump and chiller rotation, improve efficiency, and avoid simultaneous operation of high energy equipment

- AHU demand control: apply CO₂ based ventilation control to reduce energy use while maintaining IAQ

- Predictive fan and VFD monitoring: detect bearing vibration trends and schedule maintenance before failure

- Multi site energy dashboards: centralize feed of meters and compare normalized energy use across sites for portfolio level decisions

For more details on chiller plant optimization and building management, explore our service page.You may also find useful insights in reports from MarketsandMarkets, McKinsey, and other IoT industry publications.

11. Challenges and Mitigation Strategies

IoT building projects often face recurring challenges. Below are common issues with practical mitigation strategies:

- Data quality: Poor sensor calibration can reduce system accuracy. Mitigation: Standardize calibration procedures and confirm reliability through regular field audits.

- Integration complexity: Multiple vendor systems create compatibility problems. Mitigation: Apply a unified integration template and enforce clear naming conventions.

- Skills gap: Teams may lack expertise in analytics and cloud integration. Mitigation: Provide training programs and include a structured knowledge transfer schedule in the project scope.

- Security concerns: Stakeholders often worry about data safety and compliance. Mitigation: Share architecture diagrams, maintain a threat model, and conduct independent security assessments.

12. Future trends and what to plan for

Plan for the next wave of capabilities:

- AI assisted control that optimizes setpoints using weather and occupancy forecasts

- Digital twins for simulation and predictive testing of control strategy changes

- Edge computing to reduce latency and support local closed loop automation

- Wider low power connectivity for battery devices such as LoRaWAN

- Integration of sustainability reporting into building operational dashboards

13. Why Dew Tech is the right partner for the Middle East market

- Local delivery and compliance knowledge

- Hands on commissioning and optimization services

- Partnerships with EasyIO and other control vendors for integrated solutions

Suggested internal link for sales and discovery: /service/

14. Conclusion and next steps

IoT Building Automation is not a product, it is a capability set that requires strategy, engineering discipline, and operational ownership. EasyIO controllers provide the building blocks, and Dew Tech provides the local delivery capability for the Middle East.

Next steps for technical teams:

- Run a rapid site assessment for one high-priority system

- Define KPIs and success criteria for the pilot

- Plan for a phased rollout with security and operations in scope

Contact Dew Tech for a site assessment and pilot program planning.

Share

Don?t Have An Account?

Have An Account?